-40%

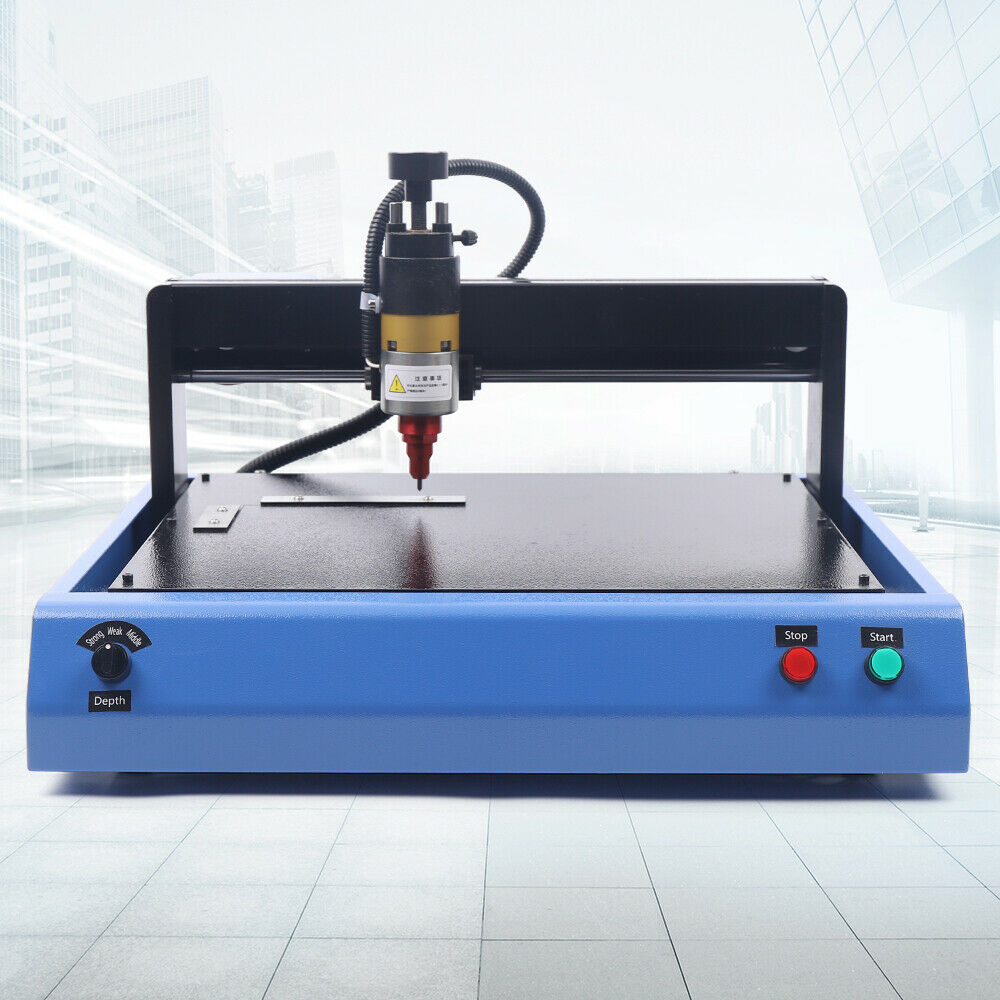

Pneumatic Marking Machine Dot Peen Engraver Flat Circle Metal Label Printer 110V

$ 365.9

- Description

- Size Guide

Description

Pneumatic Rotary Dot Peen Marking Machine for Circle & Flat Surface Marking 125*85mm Standard marking area: 125mm x 85mm Rotary fixture: Clamp the part within diameter 120mm, weight with in 5kg Marking Speed: 1 - 5 pints/s Impact Frequency: 300 times/s Repeated Accuracy: 0.001mm Marking Depth: 0.1mm~2mm(depends on material) Air power request: 0.2Mpa ~ 0.6Mpa Humidity: 0-90% (Non-condensing) Temperature: 20 - 40℃ Materials request: Below HRC60 metallic Software compatible: Windows 98/XP/7Store category

Sign Up Now !

You may also like

Pneumatic Marking Machine Dot Peen Engraver Flat Circle Metal Label Printer 110V

Product Description

KT-QD02 Industry Rotary Dot Peen Marking Machine Pneumatic CNC Engraving DPM US

Introduction:

- The Dot Peen marking machine is a pneumatic device that efficiently creates permanent marks on a variety of hard materials such as metal and plastic

125*85mm Pneumatic Dot Peen Marking Engraving Machine Nameplate Marking Engraver

Introduction:

★

The Dot Peen marking machine is a pneumatic device that efficiently creates permanent marks on a variety of hard materials such as metal and plastic.It is ideal for marking across a vast range of industries like steel,machines,electronic machinery and vehicles.

★

The machine with an additional rotary fixture base.The rotary fixture gives it extra flexibility and adaptation to mark components of literally any shape and dimension.The possibilities for engraving on flat and circular surfaces are endless.

★

The Dot Peen marking system works on air power.

★

It is programmed to work through a PC.It is shipped with the relevant software,USB and cable.

★

The rotary fixture enables excellent circle surface marking.

★

The screw holes on the table make it convenient to fix the“to-be-marked”products.

Specification:

❖

Standard marking area:125mm x 85mm

❖

Rotary fixture:Clamp the part within diameter 120mm,weight with in 5kg

❖

Marking Speed:1-5 pints/s

❖

Impact Frequency:300 times/s

❖

Repeated Accuracy:0.001mm

❖

Marking Depth:0.1mm~2mm

(

depends on material

)

❖

Air power request:0.2Mpa~0.6Mpa

❖

Humidity:0-90%(Non-condensing)

❖

Temperature:20-40℃

❖

Materials request:Below HRC60 metallic

❖

Software compatible:Windows 98/XP/7

Marking^Content:

English characters,number,all kinds of graphic,logo,dot matrix 2D codes,Barcode,Serial Number,circle Letter and etc.

Application:

1)

The dot peen marking machine is perfectly suited for use with a variety of industrial products with higher efficiency and convenience.

2)

Direct Part Marking(DPM)–This is a process of permanently marking parts with a barcode.This is done to allow the tracking of parts through the full life cycle.

■

Fitting/tube/pipe circle marking

■

Scale engraving marking

■

Nameplates marking

■

Metal parts marking(Stainless steel,brass,aluminum,copper,titanium etc.)

■

Component identification

■

Component traceability

■

Lot numbering

■

Nameplate marking

■

Cast and Forge Marking

■

Rod,engine marking

■

Gear,pump marking

■

Bowl marking

■

Part or Equipment numbering

■

Batch&Shift Coding

■

Tools marking

■

Various Metal Label Marking

. It is ideal for marking across a vast range of industries like steel, machines, electronic machinery and vehicles.

- The machine with an additional rotary fixture base. The rotary fixture gives it extra flexibility and adaptation to mark components of literally any shape and dimension.The possibilities for engraving on flat and circular surfaces are endless.

■

The Dot Peen marking system works on air power.

■

It is programmed to work through a PC. It is shipped with the relevant software, USB and cable.

■

The rotary fixture enables excellent circle surface marking.

■

The screw holes on the table make it convenient to fix the

“

to-be-marked

”

products.

Specification:

•

Standard marking area: 125mm x 85mm

•

Rotary fixture :Clamp the part within diameter 120mm, weight with in 5kg

•

Marking Speed: 1 - 5 pints/s

•

Impact Frequency: 300 times/s

•

Repeated Accuracy: 0.001mm

•

Marking Depth: 0.1mm~2mm

(

depends on material

)

•

Air power request: 0.2Mpa ~ 0.6Mpa

•

Humidity: 0-90% (Non-condensing)

•

Temperature :20 - 40

℃

•

Materials request :Below HRC60 metallic

•

Software compatible :Windows 98/XP/7

Marking Content:

English characters, number, all kinds of graphic, logo, dot matrix 2D codes, Barcode, Serial Number, circle Letter and etc.

Application:

The dot peen marking machine is perfectly suited for use with a variety of industrial products with higher efficiency and convenience.

Direct Part Marking (DPM)

–

This is a process of permanently marking parts with a barcode. This is done to allow the tracking of parts through the full life cycle.

•

Fitting/tube/pipe circle marking

•

Scale engraving marking

•

Nameplates marking

•

Metal parts marking (Stainless steel, brass, aluminum, copper, titanium etc.)

•

Component identification

•

Component traceability

•

Lot numbering

•

Nameplate marking

•

Cast and Forge Marking

•

Rod, engine marking

•

Gear, pump marking

•

Bowl marking

•

Part or Equipment numbering

•

Batch & Shift Coding

•

Tools marking

•

Various Metal Label Marking

Payment

Delivery details

Terms of sales

About us

Contact us

Payment

We accept ebay payment 。

Fees such as import duties, taxes are not included in the item price or shipping costs. These charges are the buyer's responsibility.

Delivery details

Shipping:

The item will be shipped from our US warehouse to United States, which is more faster than from aboard.

2-9 working days to: USA

Terms of sales

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

About us

Your satis

faction is our ultimate goal. We work hard to earn your trust and future business. Our certified technicians have tested each item before shipping. The unit comes with 1 year limited warranty on all manufacturing defects.

a) If you receive a defective item, you may return it or ask for a discount. Please contact us within 14 days after you receive the package.

b) What you returned must be intact and in its original packaging as re? u. Customer is responsible for shipping costs of the returned item.

c) We will cover the cost of shipping back t with the shipping rate indicated in the registration page. We will send you a new unit or refund the full payment you paid.

Thank you.

Contact us

Business Hour

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

Feedback

On Jul-05-21 at 18:53:24 PDT, seller added the following information: